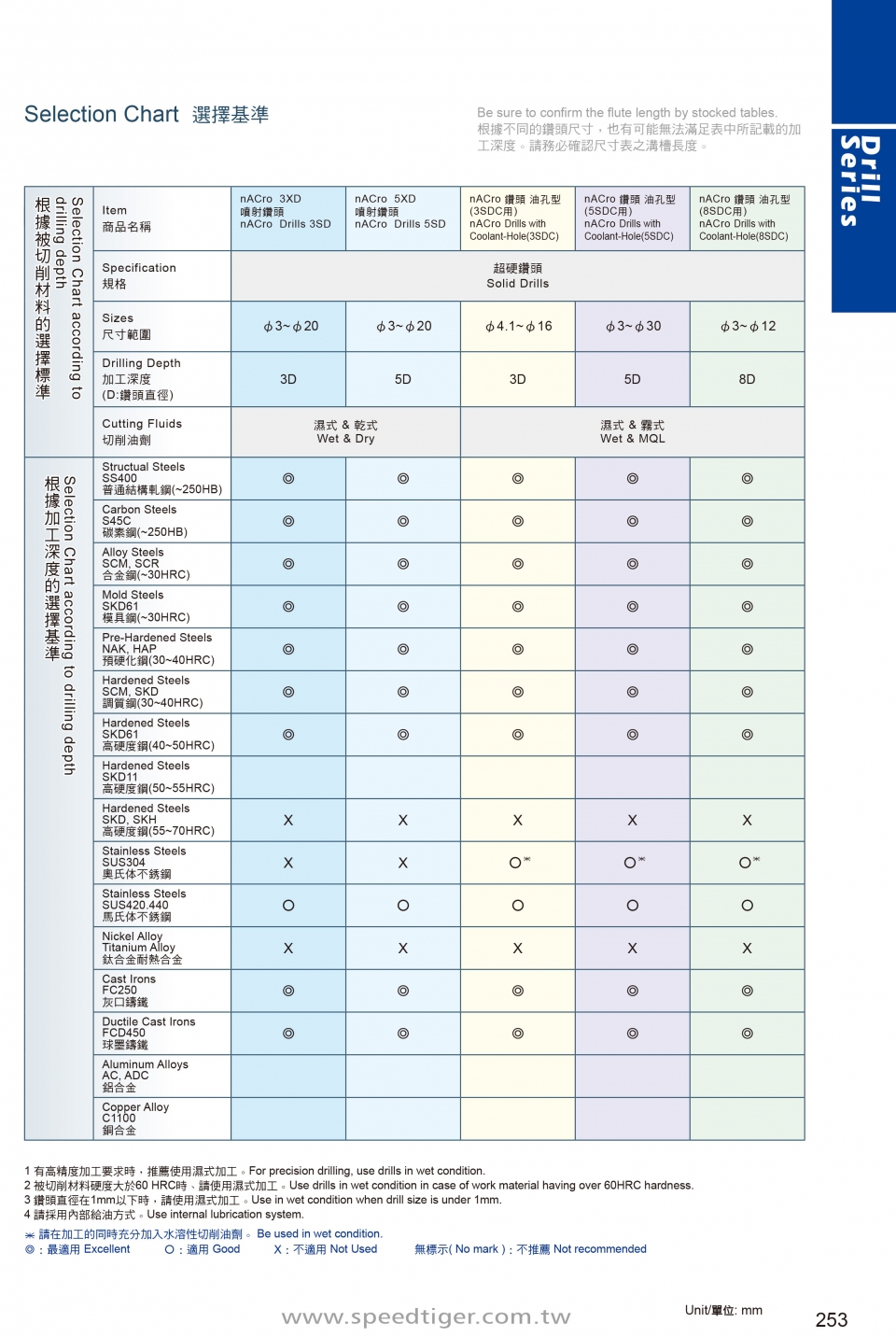

APPLICATION應用索引

-

詳細規格下載 Spec. Download

切削參數下載 Cutting Condition Download

產品介紹下載 Series Introduction Download

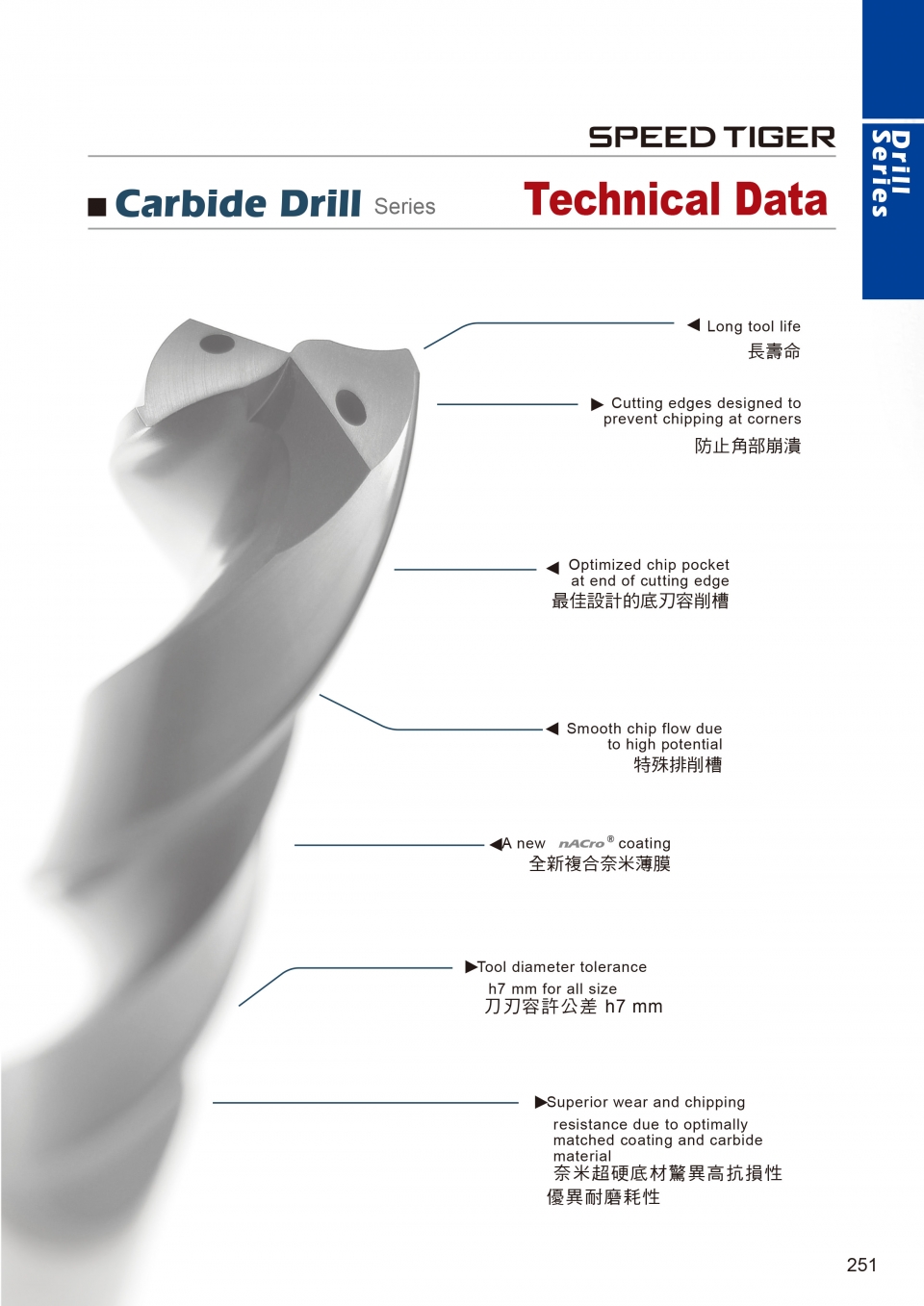

- 長壽命 Long tool life

- 防止角部崩潰 Cutting edges designed to prevent chipping at corners

- 最佳設計的底刃容削槽 Optimized chip pocket at end of cutting edge

- 特殊排屑槽 Smooth chip flow due to high potential

- 全新複合奈米薄膜 A new nACro coating

- 刀刃容許公差 h7 mm Tool diameter tolerance h7 mm for all size

- 奈米超硬底材驚異高抗損性優異耐磨耗性 Superior wear and chipping resistance due to optimally matched coating and carbide material

Carbide Drill Series

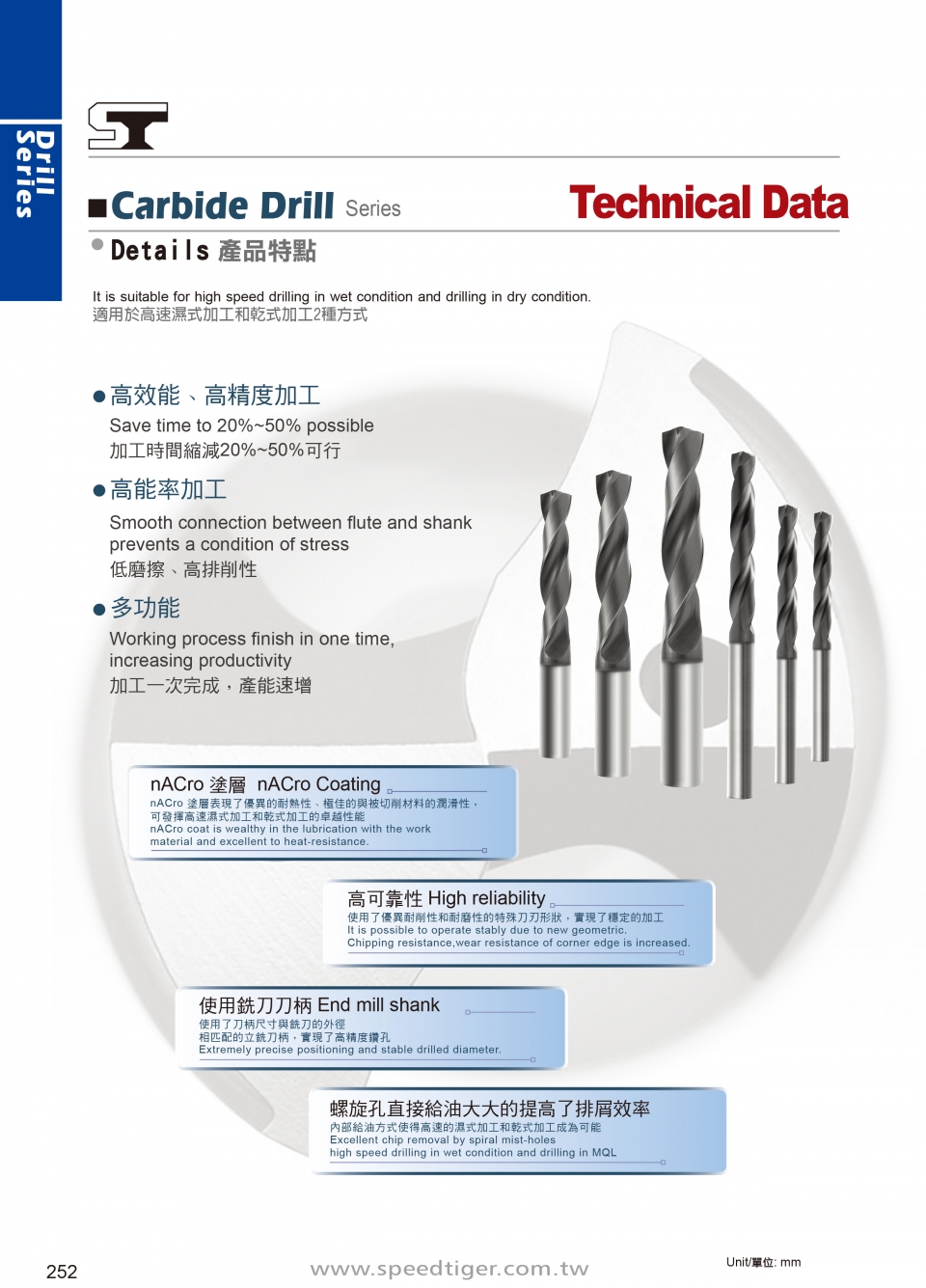

產品特點 Details

適用於高速濕式加工和乾事加工2種方式

It is suitable for high speed drilling in wet condition- 高效能、高精度加工

-加工時間縮減20%~50%可行 Save time to 20%~50% possible - 高能率加工

-低磨擦、高排削性 Smooth connection between flute and shank prevents a condition of stress - 多功能

-加工一次完成,產能速增 Working process finish in one time, increasing productivity

nACRo 塗層 nACro Coating

nACro 塗層表現了優異的耐熱性,極佳的與被切削材料的潤滑性,可發揮高速濕式加工和乾式加工的卓越性能 nACRo coat is wealthy in the lubrication with the work material and excellent to heat-resistance.

高可靠性 High reliability

使用了優異耐削性和耐磨性的特殊刀刃形狀,實現了穩定的加工

It is possible to operate stably due to new geometric. Chipping resistance, wear resistance of corner edge is increased.

使用銑刀刀柄 End mill shank

使用了刀柄尺寸與銑刀的外徑

相匹配的立銑刀柄,實現了高精度鑽孔

Extremely precise positioning and stable drilled diameter.

螺旋孔直接給油大大的提高了排屑效率

内部給油方式使得高速的濕式加工和乾式加工成爲可能

Excellent chip removal by spiral mist-holes high speed drilling in wet condition and drilling in MQL