PRODUCTSńöóÕōüń│╗ÕłŚ

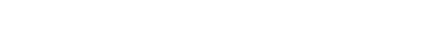

SULBT 2ÕłāķĢʵ¤äńÉāÕ×ŗń½ŗķŖæÕłĆ

ÕĢåÕōüńĘ©ĶÖ¤’╝ÜSULBT

RS ĶČģµĮżµ╗æń│╗ÕłŚ’╝īĶ”ŵĀ╝’╝Ü1mm~16mm’╝īÕĪŚÕ▒ż’╝ÜRS

-

Ķ®│ń┤░Ķ”ŵĀ╝õĖŗĶ╝ē Spec. Download

ÕłćÕēŖÕÅāµĢĖõĖŗĶ╝ē Cutting Condition Download

ńöóÕōüõ╗ŗń┤╣õĖŗĶ╝ē Series Introduction Download

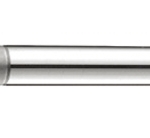

RS ĶČģµĮżµ╗æń│╗ÕłŚ RS Anti-wear Functional Series

ńףĶ¦ŻRSÕĪŚÕ▒ż

Feature of RS coating

Ō¢īµŖŚńå▒ Oxidation start temperature : 1,000Ōäā

Ō¢īńĪ¼Õ║” Hardness: 2,800HV

Ō¢īµæ®µō”õ┐éµĢĖ Coefficient of friction : 0.4

Ō¢īĶ¢äĶå£ÕÄÜÕ║” Thickness (μ) : 3~ 4 μ

ķĪÅĶē▓ Color:ķŖĆĶē▓ Silver

Ō¢īõ╣ŠŃĆüµ┐ĢÕ╝ÅÕłćÕēŖ’╝īÕŖĀÕĘźĶ╗¤µØÉńé║õĖĆĶł¼AlTiNńÜä

2Ķć│3ÕĆŹÕŻĮÕæĮŃĆé

Dry and Wet Coolant , Cutting performance of soft

material improved by 2~3 times than Altin Coating

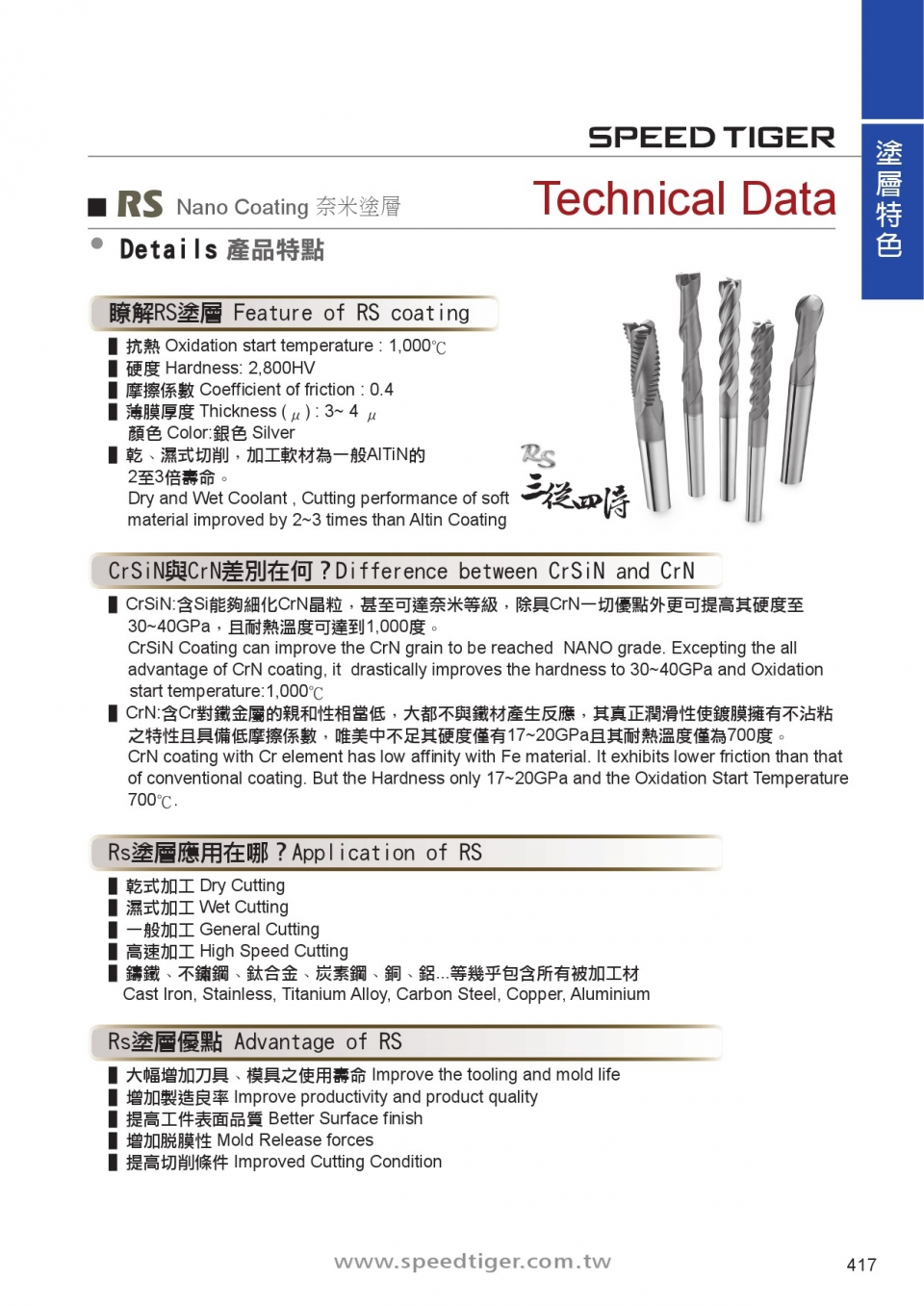

CrSiNĶłćCrNÕĘ«ÕłźÕ£©õĮĢ’╝¤Difference between CrSiN and CrN

Ō¢īCrSiN:ÕɽSiĶāĮÕżĀń┤░Õī¢CrNµÖČń▓Æ’╝īńöÜĶć│ÕÅ»ķüöÕźłń▒│ńŁēń┤Ü’╝īķÖżÕģĘCrNõĖĆÕłćÕä¬ķ╗×Õż¢µø┤ÕÅ»µÅÉķ½śÕģČńĪ¼Õ║”Ķć│

30~40GPa’╝īõĖöĶĆÉńå▒µ║½Õ║”ÕÅ»ķüöÕł░1,000Õ║”ŃĆé

CrSiN Coating can improve the CrN grain to be reached NANO grade. Excepting the all

advantage of CrN coating, it drastically improves the hardness to 30~40GPa and Oxidation

start temperature:1,000Ōäā

Ō¢īCrN:ÕɽCrÕ░ŹķÉĄķćæÕ▒¼ńÜäĶ”¬ÕÆīµĆ¦ńøĖńĢČõĮÄ’╝īÕż¦ķāĮõĖŹĶłćķÉĄµØÉńöóńö¤ÕÅŹµćē’╝īÕģČń£¤µŁŻµĮżµ╗æµĆ¦õĮ┐ķŹŹĶ壵ōüµ£ēõĖŹµ▓Šń▓ś

õ╣ŗńē╣µĆ¦õĖöÕģĘÕéÖõĮĵ段ō”õ┐éµĢĖ’╝īÕö»ńŠÄõĖŁõĖŹĶČ│ÕģČńĪ¼Õ║”Õāģµ£ē17~20GPaõĖöÕģČĶĆÉńå▒µ║½Õ║”Õāģńé║700Õ║”ŃĆé

CrN coating with Cr element has low affinity with Fe material. It exhibits lower friction than that

of conventional coating. But the Hardness only 17~20GPa and the Oxidation Start Temperature

700Ōäā.

RsÕĪŚÕ▒żµćēńö©Õ£©Õō¬’╝¤

Application of RS

Ō¢īõ╣ŠÕ╝ÅÕŖĀÕĘź Dry Cutting

Ō¢īµ┐ĢÕ╝ÅÕŖĀÕĘź Wet Cutting

Ō¢īõĖĆĶł¼ÕŖĀÕĘź General Cutting

Ō¢īķ½śķƤÕŖĀÕĘź High Speed Cutting

Ō¢īķæäķÉĄŃĆüõĖŹķÅĮķŗ╝ŃĆüķł”ÕÉłķćæŃĆüńéŁń┤Āķŗ╝ŃĆüķŖģŃĆüķŗü...ńŁēÕ╣Šõ╣ÄÕīģÕɽµēƵ£ēĶó½ÕŖĀÕĘźµØÉ

Cast Iron, Stainless, Titanium Alloy, Carbon Steel, Copper, Aluminum

RsÕĪŚÕ▒żÕä¬ķ╗×

Advantage of RS

Ō¢īÕż¦Õ╣ģÕó×ÕŖĀÕłĆÕģĘŃĆüµ©ĪÕģĘõ╣ŗõĮ┐ńö©ÕŻĮÕæĮ Improve the tooling and mold life

Ō¢īÕó×ÕŖĀĶŻĮķĆĀĶē»ńÄć Improve productivity and product quality

Ō¢īµÅÉķ½śÕĘźõ╗ČĶĪ©ķØóÕōüĶ│¬ Better Surface finish

Ō¢īÕó×ÕŖĀĶä½Ķå£µĆ¦ Mold Release forces

Ō¢īµÅÉķ½śÕłćÕēŖµóØõ╗Č Improved Cutting Condition