PRODUCTS產品系列

-

400 PLUS 奈米泛用系列 400 PLUS Nano Series General Application

適用材料: ~HRC60/ 鐵材 / 素碳鋼 / 鑄鐵 / 模具鋼 / 合金鋼 / 工具鋼 / 熱處理鋼 / 焊補鋼料

Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

主要特性:極細微粒碳化鎢母材韌性高,被覆 n.B.S ,耐磨耗,非一般鈦鋁。專用於高速 M/C 高硬度高速切削,能對熱處理模具直接進行粗加工到細加工,減少換刀次數,提高機床稼動率,節省模具製作時程。

Main Character: Ultra Fine Micro Grain Carbide that has high toughness, coating n.B.S and wear-resisting, non-general titanium aluminum is specialized in milling on M/C high hardness at a high speed and can carry on rough machining get to detailed process directly for heat treatment mould to reduce change times, improve machine flexible rate and shorten producing time.

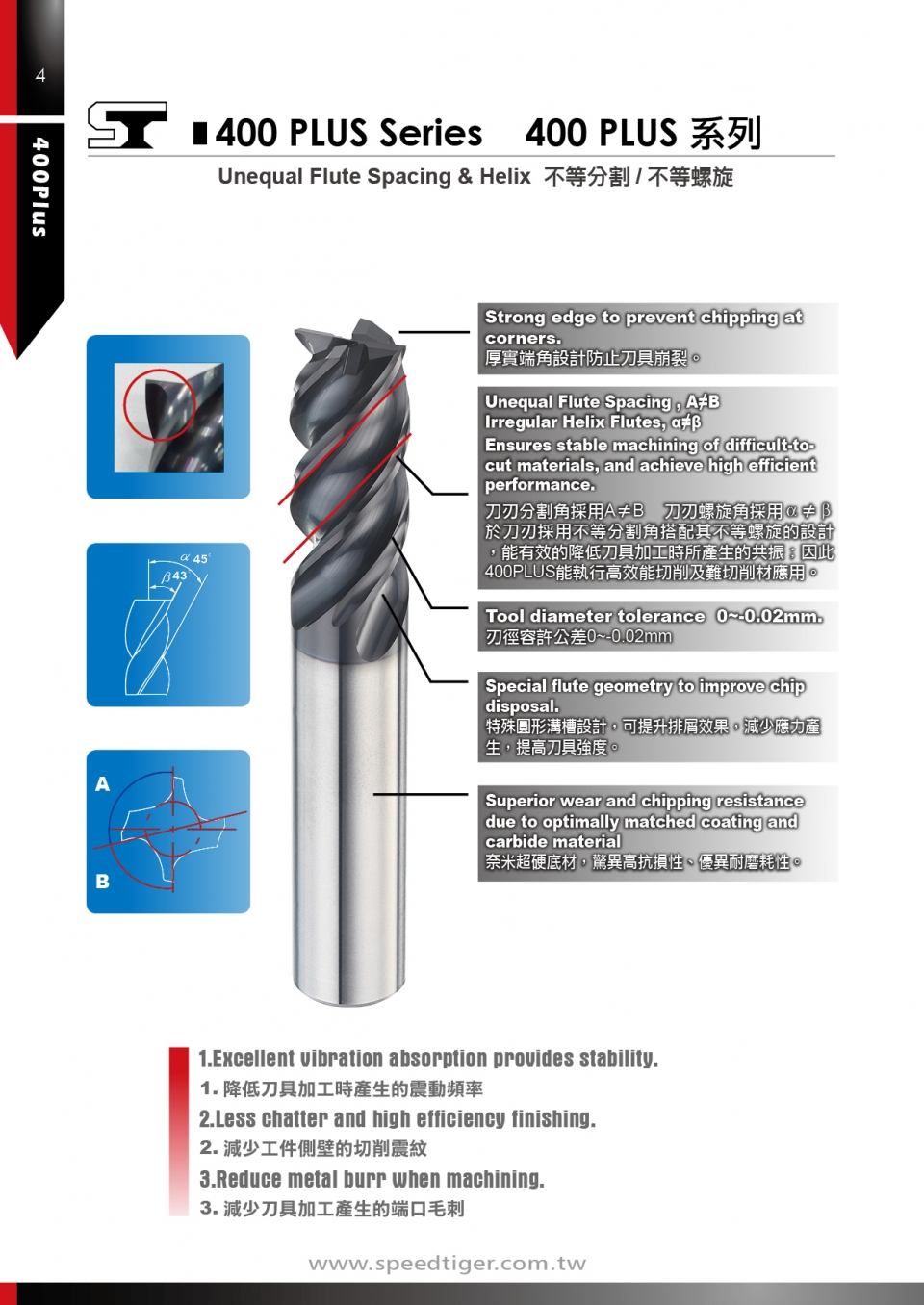

主要特色 Main Feature:- 厚實端角設計防止刀具崩裂

Strong edge to prevent chipping at corners. - 刀刃分割角採用A≠B 刀刃螺旋角採用α≠β於刀刃採用不等分割角搭配其不等螺旋的設計,能有效的降低刀具加工時所產生的共振;因此400PLUS能執行高效能切削及難切削材應用。

Unequal Flute Spacing,A≠B Irregular Helix Flutes, α≠β Ensures stable machining of difficult-to-cut-materials, and achieve high efficient performance. - 刃徑容許公差0~-0.02mm

Tool diameter tolerance 0~-0.02mm. - 特殊圓形溝槽設計,可提升排屑效果,減少應力產生,提高刀具強度。

Special flute geometry to improve chip disposal. - 奈米超硬底材,驚異高抗損性、優異耐磨耗性。

Superior wear and chipping resistance due to optimally matched coating and carbide material.✓ Exellent vibrant absorption provides stability.

Excellent vibration absorption provides stability.

✓ 減少工件側壁的切削震紋

Less chatter and high efficiency finishing.

✓ 減少刀具加工產生的端口毛刺

Reduce metal burr when machining.

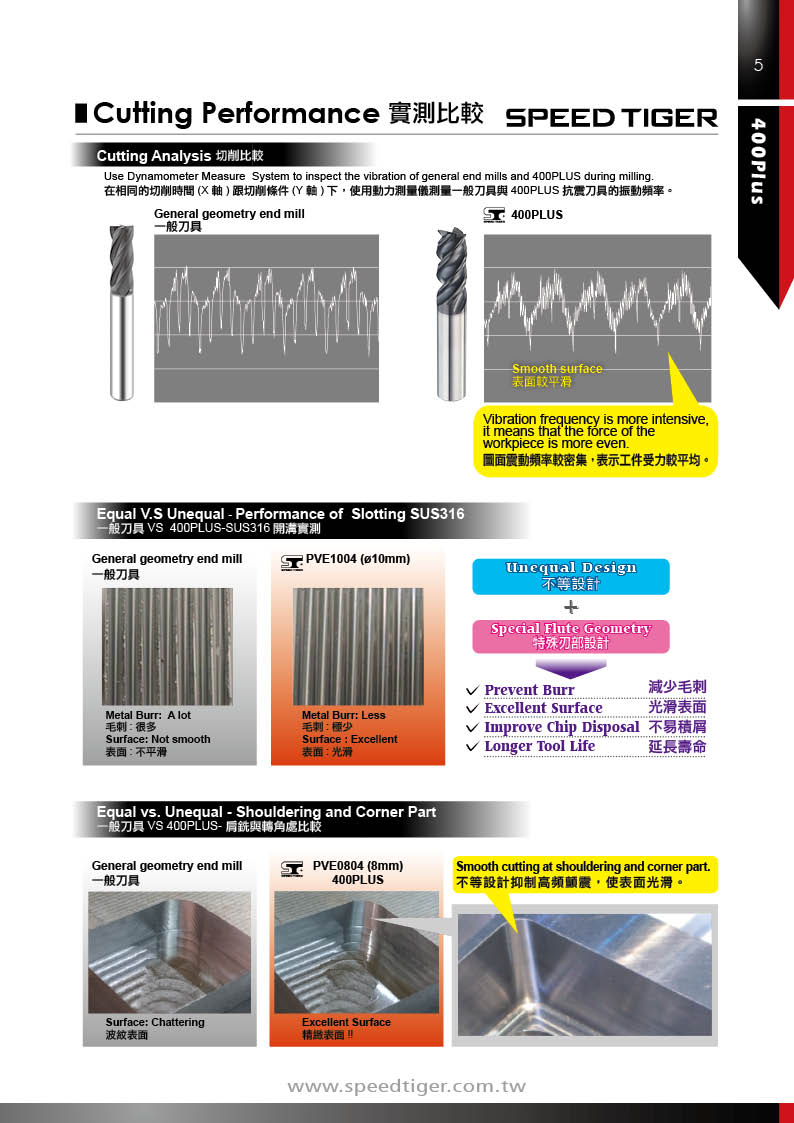

不等設計 Unequal design+特殊刃部設計 Special flute geometry :- 減少毛刺 Prevent Burr

- 光滑表面 Excellent Surface

- 不易積屑 Improve Chip Disposal

- 延長壽命 Longer Tool Life

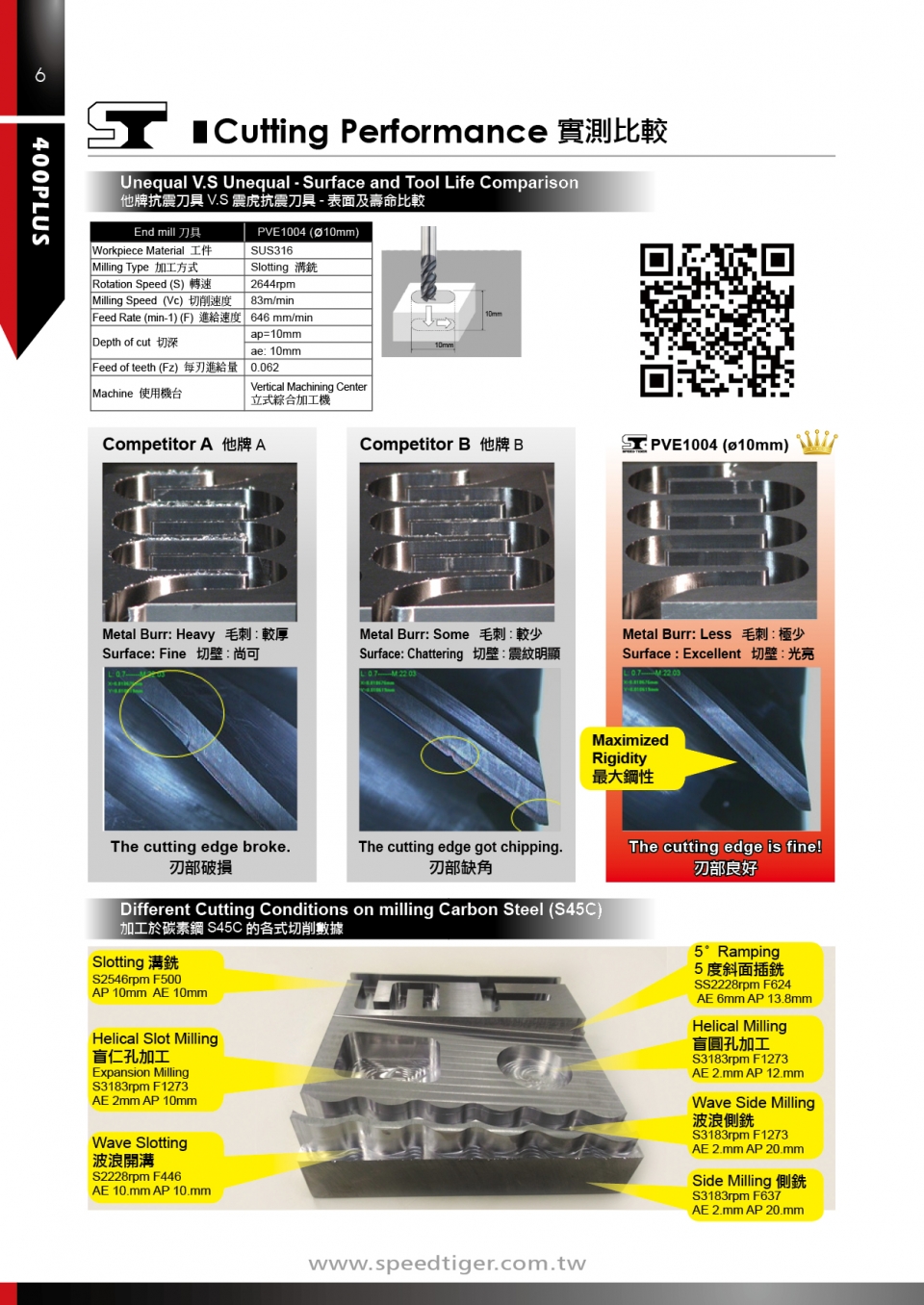

加工於碳素鋼S45C的各式切削數據

Different Cutting Condition on milling Carbon Seel (S45C)Slotting- 溝銑 Slotting

- 盲仁孔加工 Helical Slot Milling

- 波浪開溝 Wave Slotting

- 側銑 Side Milling

- 5度斜面插銑 5°Ramping

- 盲圓孔加工 Helical Milling

- 波浪側銑 Wave Side Milling

產品系列比較表 ComparisonSeries

系列Grain Size

粒徑大小Hardness

硬度 (HRC)Coating

塗層Application

應用200Nano 0.2μm ~65 TiSiN Super Hard Hardness

超高硬度應用400Nano 0.4μm ~60 nBS High Hardness

高硬度應用600Nano 0.6μm ~50 AlTiN General

一般泛用

- 厚實端角設計防止刀具崩裂