APPLICATIONµćēńö©ń┤óÕ╝Ģ

-

SH ĶČģķ½śńĪ¼Õ║” & ĶČģķ½śķƤÕŖĀÕĘźń│╗ÕłŚ Super High Hardness & Super High Speed Cutting Series

ķü®ńö©µØɵ¢Ö: ķÉĄµØÉ / ń┤Āńó│ķŗ╝ / ķæäķÉĄ / µ©ĪÕģĘķŗ╝ / ÕÉłķćæķŗ╝ / ÕĘźÕģĘķŗ╝ / ńå▒ĶÖĢńÉåķŗ╝ / ńäŖĶŻ£ķŗ╝µ¢Ö

Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

- ÕłĆÕłāÕ╣│ķĀåÕģēµ╗æ SMOOTH radiul relief

- Õźłń▒│ĶČģķ½śńĪ¼Õ║ĢµØÉŃĆüķ®ÜńĢ░ķ½śµŖŚµÉŹµĆ¦ŃĆüÕä¬ńĢ░ĶĆÉńŻ©ĶĆŚµĆ¦ Superior wear and chipping resistance due to optimally matched coating and carbide material.

- Õģ©µ¢░µ░«Õī¢ķŗüķł” A new SH AlTin coating

- ÕłāÕŠæÕ«╣Ķ©▒Õģ¼ÕĘ«0~-0.02mm Tool diameter tolerance 0~-0.02mm for all size

- ķ½śµĢłĶāĮ High efficient

- ķ½śń▓ŠÕ║” High accuracy

- ķĢĘÕŻĮÕæĮ Long tool life

Ō£öÕŖĀÕĘźµÖéķ¢ōńĖ«µĖø20%~50%ÕÅ»ĶĪī

ķ½śĶāĮńÄćÕŖĀÕĘź High energy efficiency in machining

Ō£öµ®óÕ£ōÕĮóńŗĆ’╝īÕłćÕēŖ Oval Nose shaped, increase the cutting’s contact area

Ō£öµÄźĶ¦ĖķØóń®ŹÕó×Õż¦

Ō£öÕŖĀÕĘźµÖéķ¢ōńĖ«µĖø20%~50%ÕÅ»ĶĪī

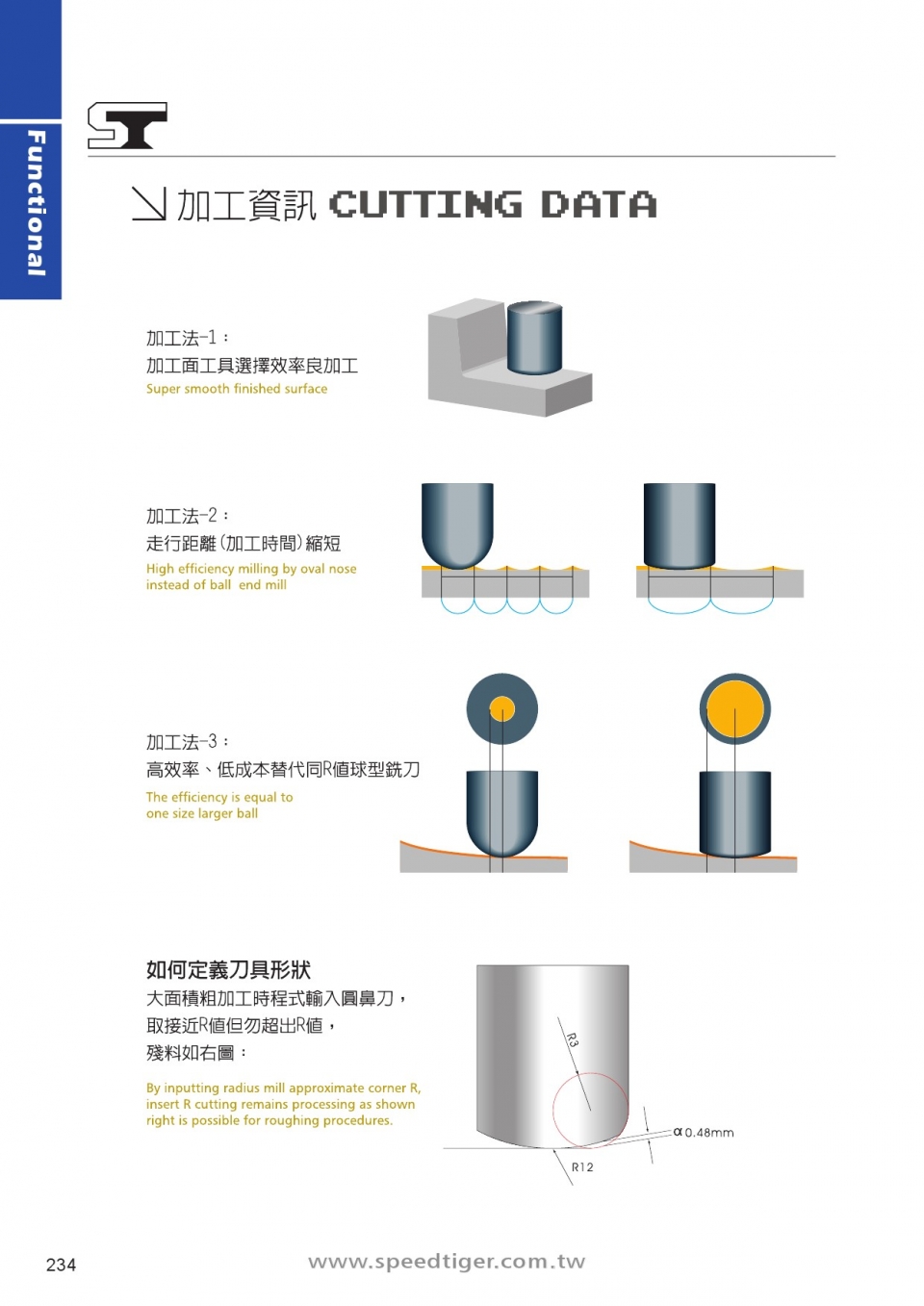

ÕŖĀÕĘźµ│Ģ 1 Method 1

ÕŖĀÕĘźķØóÕĘźÕģĘķüĖµōćµĢłńÄćĶē»ÕŖĀÕĘź Super smooth finished surface

ÕŖĀÕĘźµ│Ģ 2 Method 2

ĶĄ░ĶĪīĶĘØķøó’╝łÕŖĀÕĘźµÖéķ¢ōńĖ«ń¤Ł’╝ēHigh efficiency milling by oval nose instead of ball end mill

ÕŖĀÕĘźµ│Ģ 3 Method 3

ķ½śµĢłńÄćŃĆüõĮĵłÉµ£¼µø┐õ╗ŻÕÉīRÕĆ╝ńÉāÕ×ŗķŖæÕłĆ The efficiency is equal to one size larger ball

Õ”éõĮĢÕ«ÜńŠ®ÕłĆÕģĘÕĮóńŗĆ’╝¤How to define the tool shape?

Õż¦ķØóń®Źń▓ŚÕŖĀÕĘźµÖéń©ŗÕ╝ÅĶ╝ĖÕģźÕ£ōķ╝╗ÕłĆ’╝īÕÅ¢µÄźĶ┐æRÕĆ╝õĮåńäĪĶČģÕć║RÕĆ╝’╝īµ«śµ¢ÖÕ”éÕÅ│Õ£¢’╝Ü

By inputting radius mill approximate corner R, insert R cutting remains processing as shown right is possible for roughing procedures.

Ō£ōķ½śńĪ¼Õ║”ķŗ╝ÕŖĀÕĘźĶČģķĢĘÕŻĮÕæĮ

Ō£ōĶČģķ½śĶĪ©ķØóńĪ¼Õ║”·ĶČģķ½śķƤÕŖĀÕĘź

Ō£ōĶČģķ½śķÖäĶæŚĶ¢äĶ壷ĶČģķ½śńĪ¼Õ║”Ķ¢äĶå£

Ō£ōķ£ćĶÖÄĶłćIon Bond µŖĆĶĪōÕÉłõĮ£ķ¢ŗńÖ╝

Ō£ōLong life for high hardness steel

Ō£ōSuper high hardness, super high speed cutting

Ō£ōSuper high adhesion coating & super high hardness coating

Õźłń▒│ĶżćÕÉłÕĪŚÕ▒żµÄĪńö©Õźłń▒│µÖȵĀ╝ķØȵØÉ’╝īÕż¦Õ╣ģµö╣Õ¢äķÖäĶæŚµĢłµ×£’╝īõĖ”õĖöńČŁµīüµø┤õ║«ńÜäĶĆÉńŻ©ĶĆŚµĆ¦ŃĆé

ķØ×ÕĖĖÕć║Ķē▓Õ£░µćēńö©Õ£©ÕĪæĶåĀµ©Ī’╝īÕ░żÕģȵś»Õ£©NAKķŗ╝ÕŖĀÕĘźµĢłńÄćÕ£©2ÕĆŹõ╗źõĖŖ’╝īõĖ”õĖöÕ£©ÕÉłķćæķŗ╝NAKŃĆüńó│ķŗ╝ÕĮóµłÉĶČģķĢĘÕłĆÕģĘÕŻĮÕæĮÕÆīķ½śÕōüĶ│¬ÕŖĀÕĘźŃĆé

ńŻ©ĶĆŚõ┐éµĢĖÕż¦Õ╣ģµö╣Õ¢ä’╝īÕĮóµłÉĶ╝āõĮÄńÜäÕłćÕēŖµ║½Õ║”’╝īµēĆõ╗źõ╣ŠÕ╝ÅÕłćõ║”ÕēŖÕÅ»ĶĪī’╝īĶČģķ½śķĆ¤ÕłćÕēŖõ║”ÕÅ»ĶĪī’╝īĶČģķ½śķĆ¤ÕłćÕēŖõ║”ÕÅ»ĶĪīŃĆé

Nano-composite coating which is improved the adhesion property without making the abrassive property lower by new coating material of nano-crystal.

Excellent cutting is reached in mahcining plastic moulds, especially in NAK steels with over two times in machining efficiency. Long tool life and precision machining in carbon steels, alloy steels, NAK55 etc.

Dry cutting applicable, because of less cutting hear bt improving friction propert very much and high speed cutting applicable.